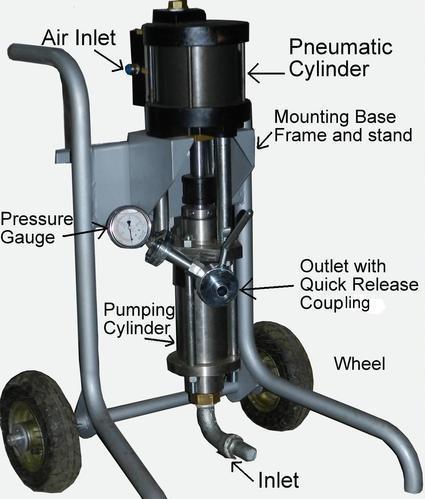

Injection grouting machine

Injection grouting machine Specification

- Flow Rate

- 8LPM

- Inlet/Outlet

- 1/4 INCH BSP

- Material

- Pu material

- Product Type

- Injection Grouting machine

- Weight

- 18 Kilograms (kg)

- Seals Type

- nylon

- Priming

- self

Injection grouting machine Trade Information

- Payment Terms

- Paypal, Cheque, Cash Advance (CA), Cash in Advance (CID)

- Main Domestic Market

- All India

About Injection grouting machine

An injection grouting machine is a piece of equipment used in construction and civil engineering to inject grout into various spaces to fill voids, cracks, or gaps in structures such as buildings, tunnels, dams, or soil. The primary purpose of this machine is to strengthen and stabilize these structures by filling these spaces with grout, which hardens and provides reinforcement.

Key Features of an Injection Grouting Machine:

- High Pressure Operation: The machine injects grout at high pressures to ensure that the material penetrates deeply into the voids or cracks.

- Versatility: Capable of handling various types of grout, including cementitious grouts, epoxy grouts, and other mixtures depending on the application.

- Durability: Designed for heavy-duty use on construction sites, with robust materials that can withstand harsh environments.

- Precision: Offers controlled injection to ensure the grout is placed accurately and effectively in the desired locations.

- Portability: Many grouting machines are designed to be portable, making them easy to transport around construction sites.

Common Applications:

- Structural Repair: Filling cracks and voids in concrete structures, such as bridges, buildings, and foundations, to restore strength and integrity.

- Waterproofing: Injecting grout into leaks or cracks in dams, tunnels, or basements to prevent water ingress.

- Soil Stabilization: Strengthening loose or unstable soil by injecting grout, often used in foundation work or to prevent landslides.

- Rock Anchoring: Used in underground mining and tunneling to secure rock formations by injecting grout into anchor holes.

Injection grouting machines are essential tools in construction, providing a reliable method for reinforcing structures and ensuring their long-term stability and safety.

4o

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grouting Pumps Category

Cement Grouting Pumps

Price 42000 / Set

Minimum Order Quantity : 1 Set

Flow Rate : 90 LPH 1800 LPH

Inlet/Outlet : 1 inch BSP

Theory : Reciprocating Pump

Pneumatic Operated Cement Grout Pump

Price 75000 / Set

Minimum Order Quantity : 1 Set

Flow Rate : 300400 liters/hour (depending on air supply)

Inlet/Outlet : Inlet: 25 mm (1), Outlet: 25 mm (1)

Theory : Other, Reciprocating pump mechanism utilizing compressed air

Standard Cement Grouting Pumps

Price Range 4200.00 - 4200.00 INR

Minimum Order Quantity : 1 Unit

Flow Rate : 140 300 LPH (Liters Per Hour)

Inlet/Outlet : 25mm / 20mm

Theory : Reciprocating Pump

Electrical Grouting Pump

Price 43000 INR / Set

Minimum Order Quantity : 1 Set

Flow Rate : 140 LPH (Liters per Hour)

Inlet/Outlet : 3/4 inch / 3/4 inch

Theory : Reciprocating Pump

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry