Tube Cement Slurry Pump

Tube Cement Slurry Pump Specification

- Voltage

- 380 V

- Mounting Type

- Horizontal

- Speed

- 1450 rpm

- Theory

- Centrifugal Pump

- Inlet/Outlet

- 80 mm / 65 mm

- Control System

- Manual/Automatic

- Working Temperature

- -20C to 120C

- Discharge Pressure

- 0.25 MPa

- Features

- High Efficiency, Corrosion Resistant, Easy Maintenance

- Flow Rate

- 60 m/h

- Max Suction

- 7 m

- Caliber

- 65 mm

- Frequency

- 50 Hz

- Noise Level

- 75 dB

- Head Size

- 18 m

- Material

- Cast Iron / Stainless Steel

- Structure

- Single Stage Pump

- Power

- 7.5 kW

- Standard

- ISO 9001

- Fuel Type

- Electric

- Pressure

- 0.3 MPa

- Usage

- Cement Slurry Transfer

- Application

- Industrial, Construction

- Suction Type

- Single Suction

- Seals Type

- Mechanical Seal

- Priming

- Self-Priming

- Pump Type

- Slurry Pump

- Capacity

- 60 m/h

- Impeller Type

- Closed Impeller

- Bearing Type

- Heavy-duty Ball Bearing

- Weight

- 240 kg

- Maximum Particle Size

- 15 mm

- Flange Type

- ANSI/DIN Standard

- Dimensions (LxWxH)

- 1200 x 450 x 620 mm

- Shaft Material

- High Strength Alloy Steel

- Color

- Blue / Customized

Tube Cement Slurry Pump Trade Information

- Minimum Order Quantity

- 1 Set

- Delivery Time

- 1-10 Days

- Main Domestic Market

- All India

About Tube Cement Slurry Pump

High Efficiency and Durability

Designed with a closed impeller and constructed from either cast iron or stainless steel, the Tube Cement Slurry Pump delivers excellent efficiency and enhanced corrosion resistance, reducing downtime and maintenance costs. Its self-priming and single-suction design allow smooth operation, while the heavy-duty ball bearings ensure longevity even in demanding industrial settings.

Versatile Application and Customization

With its standardized ANSI/DIN flange options and customizable color, this pump can be easily integrated into a variety of cement slurry transfer processes. It is compatible with automated or manual control systems, adapting to specific site requirements in industrial, construction, and manufacturing applications.

Easy Maintenance and Reliable Operation

The pump is engineered for straightforward servicing, thanks to its mechanical seal design and high-strength alloy steel shaft. Regular maintenance is simplified, and operational reliability is enhanced, ensuring sustained performance with minimal interruption.

FAQs of Tube Cement Slurry Pump:

Q: How does the Tube Cement Slurry Pump handle abrasive cement particles?

A: The closed impeller and robust mechanical seal of the pump are specifically designed to manage abrasive cement slurries containing particles up to 15 mm. Its materials, including cast iron or stainless steel, are chosen for their superior corrosion and wear resistance, extending pump life even in harsh environments.Q: What are the main benefits of using this pump for cement slurry transfer?

A: This pump offers high efficiency, reliable performance, and easy maintenance. Its heavy-duty design ensures continuous operation, while the self-priming feature and potent 7.5 kW electric motor maintain consistent slurry flow. The use of ISO 9001 manufacturing standards guarantees quality and operational safety.Q: When is it advisable to use a self-priming, single-stage slurry pump like this?

A: Self-priming, single-stage slurry pumps are ideal when frequent starts and stops are expected or where reliable priming is required after periods of inactivity. They are especially suitable for construction and industrial sites handling abrasive materials such as cement slurry.Q: Where can this cement slurry pump be installed and used?

A: The pump is suitable for horizontal installation in industrial facilities, construction sites, and plants requiring slurry transfer. Its ANSI/DIN-standard flange ports and compact dimensions (1200 x 450 x 620 mm) allow integration into existing piping networks or modular setups.Q: What is the process for maintaining and servicing the pump?

A: Routine maintenance involves checking and lubricating the heavy-duty ball bearings, inspecting the mechanical seal, and cleaning the impeller and volute. Its accessible structure simplifies these tasks, helping prevent downtime and optimize performance.Q: How does the pump perform under varying environmental conditions?

A: The pump is constructed to operate reliably within a temperature range of -20C to 120C, offering consistent results in both hot and cold climates. Its design allows for safe cement slurry transfer even under extreme weather or operational scenarios.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grouting Pumps Category

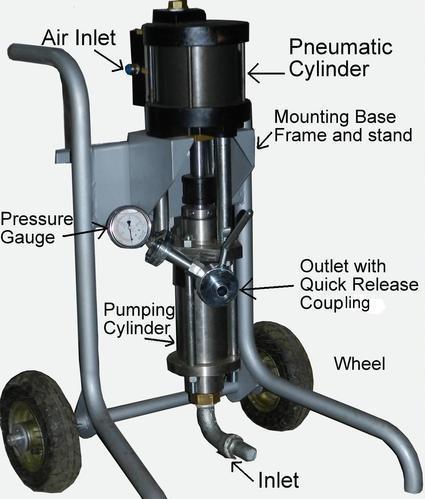

Pneumatic Operated Cement Grout Pump

Price 75000 / Set

Minimum Order Quantity : 1 Set

Usage : Other, Cement grouting for construction, bridges, and tunnels

Material : Mild steel/Alloy steel body with anticorrosion coating

Head Size : Up to 40 meters

Cement Grouting Pumps

Price 42000 / Set

Minimum Order Quantity : 1 Set

Usage : Other, Cement grouting, civil construction

Material : Highgrade Cast Iron & Mild Steel

Head Size : 12 to 40 meters

Standard Cement Grouting Pumps

Price Range 4200.00 - 4200.00 INR

Minimum Order Quantity : 1 Unit

Usage : Other, Cement Grouting

Material : Mild Steel / Cast Iron

Head Size : Upto 40 meters

Electrical Grouting Pump

Price 43000 INR / Set

Minimum Order Quantity : 1 Set

Usage : Other, Grouting, Construction Works

Material : Mild Steel

Head Size : Up to 40 meters

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry