Call: 08045479930

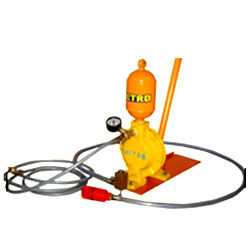

High Pressure Cement Grout Pumps

MOQ : 1 Unit

High Pressure Cement Grout Pumps Specification

- Working Temperature

- -10C to +60C

- Frequency

- 50 Hz

- Features

- Robust construction, Easy maintenance, Portable, High efficiency

- Mounting Type

- Base Mounted

- Max Suction

- 6 meters

- Caliber

- 25 mm

- Noise Level

- <70 dB

- Theory

- Reciprocating Pump

- Discharge Pressure

- Up to 100 bar

- Inlet/Outlet

- 25 mm / 19 mm

- Head Size

- 100-200 meters

- Fuel Tank Capacity

- n/a (Electric Driven)

- Control System

- Manual / Electrical Control Panel

- Voltage

- 220V / 380V

- Speed

- 1440 RPM

- Flow Rate

- 150-300 LPH

- Material

- Mild Steel / Stainless Steel

- Structure

- Piston Pump

- Power

- 2 HP / 3 HP

- Standard

- ISI Certified

- Fuel Type

- Electric

- Pressure

- 40-100 bar

- Usage

- Grouting, Cement Slurry Injection

- Application

- Bridge, Tunnel, Construction, Mining

- Suction Type

- Positive Displacement

- Seals Type

- High Pressure Packing Seals

- Priming

- Self Priming

- Pump Type

- High Pressure Cement Grout Pump

- Capacity

- 300 LPH

- Painting/Finishing

- Powder Coated / PU Painted

- Maximum Solid Content

- Up to 70%

- Corrosion Resistance

- Yes

- Mobility

- Trolley Mounted Optional

- Safety Devices

- Pressure Relief Valve

- Grout Ratio

- Up to 1:7 (Cement:Water)

- Hose Length

- 10 meters standard

- Pump Weight

- 50-75 kg approx.

- Lubrication

- Splash Lubrication

High Pressure Cement Grout Pumps Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- Unit

- Delivery Time

- 1-10 Days

- Sample Available

- No

- Packaging Details

- As per requirement

- Main Domestic Market

- All India

About High Pressure Cement Grout Pumps

We manufacture and supply a wide range of High Pressure Cement Grout Pumps, which is used for medium and large sized pre-stressed concrete works. These hand operated diaphragm pumps are provided with air chamber that helps to develop pressure up to 10kgs/cm2 (140psi). This delivers 300 liters of neat grout per hour.Features of High Pressure Cement Grout Pumps:

- Weight is 15kgs approx and is easy to carry along on scaffoldings or limited movement areas

- Designed in molded brass valve and completely detachable on the suction end

- Cleaning very easy hence avoiding opening of pump body unit completely

- Recommended to use specially designed anchorage nozzle for optimum performance of grout pump

Robust and Portable Design

Manufactured using high-grade mild steel or stainless steel, these grout pumps ensure durability and resilience against harsh environments. The option for trolley mounting makes them easy to transport across challenging worksites, while their powder-coated or PU-painted finish provides superior corrosion resistance, ideal for long-term outdoor applications.

High Performance and Efficiency

Designed with a reciprocating piston mechanism, these pumps handle thick cement slurries and maintain solid content up to 70%. Their positive displacement suction type ensures constant flow rates (150300 LPH) even under high discharge pressure, up to 100 bar, while self-priming capabilities simplify start-up and reduce downtime.

User-Friendly Operation and Safety

Equipped with a manual or electrical control panel, these pumps are easy to operate and maintain. Safety is enhanced by integrated pressure relief valves. With low noise levels (<70 dB) and splash lubrication, the pumps offer smooth, reliable functioning on any project site.

FAQs of High Pressure Cement Grout Pumps:

Q: How is a high pressure cement grout pump typically used in construction projects?

A: High pressure cement grout pumps are primarily employed for grouting, cement slurry injection, and structural rehabilitation in construction, tunnels, bridges, and mining sites. They deliver precise, controlled application of grout to fill gaps, cracks, or cavities, improving structural integrity and water resistance.Q: What advantages does splash lubrication offer for grout pumps?

A: Splash lubrication minimizes component wear by ensuring consistent oil coverage of moving parts, enhancing pump lifespan and reducing maintenance needs. This design supports prolonged, uninterrupted operation in demanding environments.Q: When should you opt for a trolley-mounted grout pump?

A: Trolley-mounted models are ideal when frequent relocation of the pump is necessary, especially in large or multi-zone construction sites. The integrated wheels and handle simplify movement, saving time and labor compared to fixed-base models.Q: What process should be followed before starting grouting with the pump?

A: Before operation, ensure the pump is properly primed using its self-priming feature, check all connections, verify correct grout mix ratio (up to 1:7 cement:water), and inspect the pressure relief valve. Confirm the control panel settings and test for leaks or blockages in the hose before full-scale grouting.Q: Where can these pumps be effectively deployed?

A: These pumps are suitable for bridge and tunnel construction, mining operations, and large-scale rehabilitation tasks, thanks to their high pressure capacity, robust construction, and resistance to corrosion. Their performance and mobility make them adaptable to both indoor and outdoor environments.Q: What are the key benefits of using ISI certified high pressure grout pumps?

A: ISI certification ensures the pump meets stringent industry standards for safety, performance, and reliability. Users benefit from enhanced operational safety, guaranteed quality, and compliance with Indian construction norms.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hydraulic Test Pump Category

Industrial hydro jet machine

Price 75000.0 INR

Minimum Order Quantity : 1

Theory : Jet Pump

Voltage : 110215 Volt (v)

Usage : Industrial

Inlet/Outlet : 1/2inch

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry